Introduction

In the field of pipeline corrosion control, cased crossings present significant challenges to maintaining structural integrity. Steel casings, designed to shield carrier pipes beneath infrastructure such as roads and railroads, can sometimes obscure the presence of electrical shorts between the carrier pipe and the casing. Determining whether a true metallic short exists is critical, particularly when pipe-to-soil potentials appear similar, which may suggest either metallic contact or an electrolytic pathway. The Panhandle Eastern Casing Test, originally developed by Panhandle Eastern Pipeline Company, provides a reliable method for making this distinction. This test has been widely adopted in the industry and is supported by standards from organizations such as AMPP (NACE) and the American Gas Association (AGA).

This guide offers a thorough examination of the Panhandle Eastern Casing Test, including its rationale for effectiveness in ambiguous scenarios, the complete procedural steps, the underlying principles, data interpretation, and a sample question-and-answer section. Our objective is to equip corrosion technicians with the tools to implement this test confidently, ensuring enhanced pipeline safety and compliance. By incorporating this method into your routine assessments, you can achieve greater precision in identifying issues, thereby optimizing maintenance strategies and extending asset longevity.

The Value of the Panhandle Eastern Casing Test in Corrosion Control

Cased pipelines are integral to protecting carrier pipes from external forces, but they introduce complexities in cathodic protection (CP) systems. Ideally, the carrier pipe remains electrically isolated from the casing through the use of insulating spacers, end seals, and protective coatings. However, factors such as soil movement, installation defects, or degradation over time can result in unintended contact. A metallic short—direct metal-to-metal connection—impedes CP current from reaching the carrier pipe, increasing corrosion risk. In contrast, electrolytic contacts, such as those caused by conductive fluids or soil in the annular space, allow some CP penetration but with reduced efficiency.

The challenge intensifies when routine pipe-to-soil (P/S) potential measurements for the carrier and casing are nearly identical, for instance, both registering around -0.85 V versus a copper/copper sulfate electrode (CSE). This similarity could indicate a metallic short or merely an electrolytic bridge, and static surveys alone often fail to differentiate. The Panhandle Eastern Casing Test addresses this by introducing a dynamic element: applying controlled DC current to depolarize the casing and observe the differential responses in potentials.

This test is particularly effective in such cases because it does not depend solely on equilibrium readings. Instead, it applies stress to the system, revealing the nature of any electrical continuity. Industry references, including the AGA's study on cathodic protection in cased pipelines and NACE SP0200, endorse this approach for its accuracy in verifying isolation. Implementing the test aligns with regulatory requirements from bodies like the Pipeline and Hazardous Materials Safety Administration (PHMSA), facilitating comprehensive CP coverage.

Detailed Procedure for Conducting the Panhandle Eastern Casing Test

The Panhandle Eastern Casing Test is accessible to corrosion technicians equipped with standard CP tools, including a variable DC power source (e.g., a rectifier or battery system capable of delivering 0-20 A or higher), a high-impedance voltmeter, a CSE reference electrode, test leads, an ammeter, and a temporary ground bed. Prioritize safety by using personal protective equipment, locating underground utilities, and ensuring electrical isolation to prevent hazards. Allocate approximately half a day per test site, depending on accessibility.

The procedure is divided into preparation, current application, and post-test activities. Assume access to the carrier pipe and casing via test stations or vent pipes.

Preparation and Baseline Measurements

Site Preparation: Inspect the cased crossing and identify access points for the carrier pipe and casing. Remove any surface contaminants to ensure reliable electrical connections.

Temporary Ground Bed Installation: Establish a ground bed to serve as the cathode, consisting of steel rods driven into moist soil approximately 10-20 feet from the casing. Connect this to the negative terminal of the DC source to facilitate current flow without impacting existing CP systems.

Baseline Potential Recordings: Without applied current, measure:

Carrier pipe-to-soil (P/S) potential: Position the CSE over the carrier pipe near the casing end, connecting the voltmeter positive lead to the pipe test point and negative to the CSE.

Casing-to-soil (C/S) potential: Use the same CSE placement, with the positive lead on the casing.

Pipe-to-casing (P/C) potential: Measure directly between the pipe and casing leads. Interrupt any active CP if feasible to obtain native potentials, though the test can proceed with CP engaged.

Stability Verification: Monitor for potential fluctuations indicative of stray currents (e.g., from nearby infrastructure). If instability is observed, postpone the test or employ mitigation techniques.

Application of Test Current

This phase involves treating the casing as the anode by directing positive DC current from it to the ground bed, thereby depolarizing the casing.

Circuit Configuration: Attach the DC source positive terminal to the casing and negative to the ground bed. Integrate an ammeter (or shunt) to monitor current output.

Incremental Current Application: Start at 0 A, then increase in steps such as 1 A, 2 A, 5 A, 10 A, and up to 20 A, maintaining each level for 1-2 minutes to allow stabilization.

Data Collection: At each current increment, record P/S, C/S, and P/C potentials, along with the source voltage to ensure operational safety.

Observation of Responses: Note potential shifts; if depolarization is not evident, verify connections.

Current Reduction: Gradually decrease to 0 A and recheck baseline potentials to confirm system recovery.

Post-Test Activities

Disassembly: Remove all temporary connections and restore the site to its original condition.

Data Organization: Compile results in a tabular or graphical format, such as plotting potentials against current.

Documentation: Prepare a report detailing findings, including photographic evidence, in accordance with organizational standards.

Practical considerations include using a variable resistor for precise current adjustment and moistening the ground bed in arid conditions to enhance conductivity. For extended casings, perform measurements at both ends. This structured approach ensures reproducibility and reliability.

Underlying Principles: Why the Test is Effective

The Panhandle Eastern Casing Test is grounded in electrochemical and electrical principles, specifically leveraging depolarization and resistance analysis to discern contact types. In a CP system, the carrier pipe is polarized negatively to inhibit corrosion. An isolated casing maintains its own potential influenced by surrounding soil. A metallic short merges the two into a single electrochemical entity, equalizing potentials and obstructing CP efficacy.

By applying positive current to the casing, the test induces anodic depolarization, shifting the casing potential positively as current discharges to earth. This counters cathodic polarization effects. The response depends on isolation status:

Isolated Configuration: The casing potential becomes less negative (e.g., from -0.6 V to -0.3 V) with increasing current, while the carrier pipe may polarize further negatively due to incidental current pickup. The P/C differential widens, reflecting the absence of a low-resistance path.

Metallic Short: Current traverses the short, depolarizing both structures synchronously. Potentials shift positively in tandem, with minimal P/C variation, consistent with low resistance (<0.01 Ω).

Electrolytic Contact: Higher resistance (0.1-1 Ω) permits partial separation, but less pronounced than in isolation.

This methodology excels when baseline potentials are similar because it introduces a variable (current) to expose resistance differences, per Ohm's Law (V = IR). Metallic shorts exhibit negligible IR drops, maintaining potential lockstep, whereas electrolytic paths show measurable drops. The AGA study and AMPP (NACE) validate this through empirical data across diverse environments, demonstrating the test's robustness in varying soil resistivities.

From a thermodynamic perspective, the test manipulates polarization curves, where applied current alters the electrode potential based on Tafel slopes. In isolated cases, the casing's curve shifts independently; in shorted scenarios, a unified curve emerges. This scientific foundation underpins the test's diagnostic precision.

Interpreting Test Data: Insights for Decision-Making

Effective data analysis is key to deriving actionable conclusions. Graph C/S and P/S potentials (y-axis, -V vs. CSE) against applied current (x-axis, A) to identify patterns.

Isolated Casing: The C/S curve rises (less negative, e.g., -0.7 V at 0 A to -0.2 V at 10 A). P/S may decrease (more negative, e.g., -0.85 V to -0.95 V) or remain stable. P/C increases substantially (e.g., 0.1 V to 0.7 V), confirming separation and adequate CP access.

Metallic Short: Curves for P/S and C/S align closely, both shifting positively (e.g., -0.8 V to -0.4 V). P/C remains near 0 V across currents, necessitating remedial actions such as excavation or dielectric filling.

Electrolytic Contact: Moderate tracking occurs, with C/S shifting more than P/S, and P/C increasing modestly. This may require monitoring or minor interventions like annulus drying.

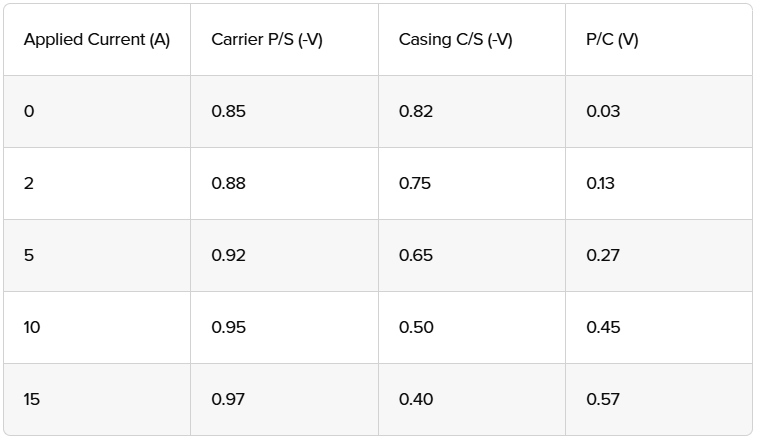

Consider the following sample data table from a hypothetical test:

Here, the growing P/C indicates isolation. A P/C variation of less than 0.1 V at 10 A would suggest a short. Apply thresholds judiciously, considering soil resistivity; higher resistivities may demand elevated currents. Integrate with complementary tests, such as four-wire resistance measurements, for validation.

Sample Question-and-Answer Session on the Panhandle Eastern Casing Test

To facilitate practical application, the following addresses common inquiries:

Question: If baseline potentials are identical at -0.84 V, does this confirm a short? Answer: Not conclusively, as it could stem from an electrolytic connection. Conduct the test: A P/C separation exceeding 200 mV at 10 A suggests electrolytic contact, potentially manageable with existing CP. Minimal separation indicates a metallic short, warranting intervention.

Question: What if achieving sufficient current is difficult? Answer: This may result from high soil resistance or a dry annulus. Enhance ground bed conductivity by adding moisture or rods. Persistent issues could imply inherent isolation, verifiable through additional resistance assessments.

Question: How does active CP affect the test? Answer: It may influence baselines, but relative shifts remain informative. Interrupt CP if possible; otherwise, emphasize differential changes.

Question: What is the recommended testing frequency? Answer: Annually for high-risk casings, or every 3-5 years as per regulatory guidelines. Longitudinal data tracking enhances predictive maintenance.

Question: Are false positives common? Answer: Infrequent, though stray currents can interfere. Schedule tests during low-interference periods and corroborate with multiple techniques.

Conclusion: Advancing Pipeline Integrity Through Informed Testing

The Panhandle Eastern Casing Test represents a cornerstone methodology for resolving uncertainties in cased pipeline assessments. By systematically applying current and analyzing potential responses, technicians can distinguish between isolation, metallic shorts, and electrolytic contacts with high accuracy.

We encourage you to apply this test in your operations, leveraging the insights provided to enhance decision-making. For further assistance, including training or specialized equipment, please contact our team.

Roberts Corrosion Services, LLC

Established in 2011, Roberts Corrosion Services, LLC delivers comprehensive, turn-key cathodic protection and corrosion control solutions nationwide. Our end-to-end expertise encompasses design and inspection, installation and repair, surveys and remedial work. We provide drilling services for deep anode installations and a full laboratory for analysis of samples and corrosion coupons, as well as custom CP Rectifier manufacturing.

While our initial focus was on the Appalachian Basin area, we complete field work all over the US. We are a licensed contractor in many states and can complete a wide range of services.

Our biggest strength is in our flexibility for our clients. Solutions and Results.

Let us know how we can help.

Website

LinkedIn

Location: 39.251882, -81.047440

(304) 869-4007