Holiday Detection for New Pipelines & Debunking Common Myths

Introduction

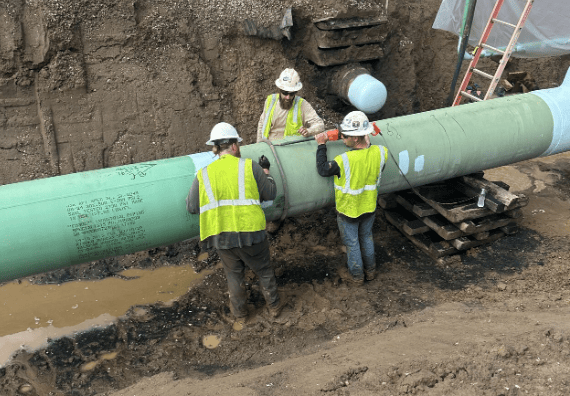

Investing in new pipeline infrastructure represents a huge commitment of capital, time, and resources. With the global pipeline construction market projected to reach $73.1 billion by 2031, ensuring the long-term integrity and safety of these assets has never been more critical. The first line of defense against the threat of corrosion is the pipeline's protective coating system. However, a coating is only as effective as its weakest point. This is where the updated standard, NACE SP0188-2024, becomes an indispensable guide for asset owners, engineers, and inspectors, providing a modern, science-backed framework for ensuring coating integrity from day one.

The Role of Coating Integrity in Pipeline Longevity

Protective coatings are the primary barrier between a steel pipeline substrate and its environment. A continuous coating prevents moisture and corrosive elements from reaching the steel, effectively stopping the electrochemical process of corrosion. When this barrier is broken, even by a microscopic pinhole, localized corrosion can lead to metal loss and eventual failure. Given that external corrosion represents a large percent of pipeline failures, the initial quality of the coating system is a direct predictor of the pipeline's service life and operational safety.

Holiday Detection is a Must for New Pipelines

A "holiday" is any discontinuity in a protective coating. A pinhole, crack, void, or thin spot that exposes the underlying substrate. Holiday detection, also known as discontinuity (holiday) testing, is the process of locating these defects. For new pipelines, this inspection is not just a quality control checkpoint; it is a fundamental step in risk mitigation. Performing thorough holiday/pinhole detection before a pipeline is buried or submerged is the only opportunity to find and repair these defects cost-effectively.

NACE SP0188-2024

To standardize this process, the industry relies on standards developed by organizations like the Association for Materials Protection and Performance (AMPP), formerly known as NACE International. The newly released NACE SP0188-2024, "Discontinuity (Holiday) Testing of New Protective Coatings on Conductive Substrates," represents the latest in best practices. It supersedes the previous 2006 version, introducing significant updates that align testing procedures with modern coating technology and a more scientific understanding of electrical principles, ensuring a more reliable and defensible inspection process for new pipeline projects.

Understanding Holiday Detection

At its core, holiday detection is a non-destructive test method used to locate gaps in a non-conductive protective coating applied to a conductive substrate, such as steel. It is an essential quality assurance step that verifies the coating is a continuous barrier, ready to provide protection.

Defining Discontinuity (Holiday) Testing

Discontinuity (holiday) testing involves creating an electrical circuit through the inspection equipment, the coating, and the steel substrate. The inspector moves an electrode over the coated surface. When the electrode passes over a defect, the electrical current flows from the electrode through the defect to the substrate, completing the circuit. This completion triggers an audible and/or visual alarm on the holiday detector, precisely identifying the location of the defect for marking and repair. This process is often referred to as "jeeping," "spark testing" (for high voltage methods), or simply pinhole detection.

The "Why"

The primary reason for performing holiday detection is to prevent corrosion. The annual cost of pipeline corrosion in the oil and gas industry is huge, estimated at $7 billion. A small holiday can act as an anode in a corrosion cell, concentrating corrosion on a small area of exposed steel. By finding and repairing these defects before the pipeline enters service, holiday detection directly prevents the initiation of these localized corrosion sites, safeguarding the asset.

A coating system with undetected holidays will underperform significantly. These defects allow moisture to penetrate to the substrate, which can lead to blistering, delamination, and under-film corrosion that spreads outward from the initial flaw. Furthermore, holidays can compromise the effectiveness of cathodic protection (CP) systems. CP systems are designed to protect minor defects, but a high density of holidays increases demand, causing it to consume sacrificial anodes or impressed current at an accelerated rate. A coating free of discontinuities works with the CP system, ensuring efficient, long-term protection.

Differentiating Low Voltage vs. High Voltage Holiday Detection Principles

The choice between low voltage and high voltage holiday detection is dictated primarily by the coating thickness.

Low Voltage Holiday Detection: This method, often called the "wet sponge" technique, is suitable for testing non-conductive coatings up to 20 mils thick. It uses a low DC voltage (typically 5, 9, 67.5, or 90V). A sponge, saturated with a conductive solution (tap water with a wetting agent), is passed over the coating. When the wet sponge encounters a holiday, the solution penetrates the defect and completes the electrical circuit to the substrate, triggering an alarm.

High Voltage Holiday Detection: This method uses a significantly higher DC or pulsed DC test voltage to create a spark (an electrical arc) that jumps from the electrode through the air gap of the holiday to the substrate. This spark completes the circuit and activates the alarm. The required test voltage is carefully calculated based on the coating thickness and its dielectric strength to ensure it is high enough to detect flaws but not so high as to damage the coating.

NACE SP0188-2024 and Its Impact on New Pipelines

Industry standards are not static; they evolve to incorporate new research, technologies, and field experience. The transition from NACE SP0188-2006 to the 2024 version marks a significant step forward in ensuring the reliability of discontinuity testing, particularly for the advanced coating systems used on new pipelines.

Why the Update Was Necessary

The 2006 version of SP0188 served the industry well, but coating technology and our understanding of electrical principles have advanced. The older standard contained voltage-setting guidelines that were often interpreted as simple "volts-per-mil" rules of thumb. While easy to apply, these rules didn't fully account for the complex physics of electrical arcing or the varying properties of different coating systems. The 2024 update was necessary to move the industry away from these potentially inaccurate generalizations toward a more scientifically grounded approach, ensuring that the test is both effective and non-destructive.

Key Changes and Updates

The most significant change in NACE SP0188-2024 is the formal adoption of voltage calculation methodologies based on established electrical principles, specifically Paschen's Law. Paschen's Law describes the voltage required to initiate an electrical arc or spark between two electrodes in a gas. In this case, between the detector's electrode and the pipe substrate through the air in a holiday. This approach recognizes that the required voltage is not a simple linear function of coating thickness. The standard now provides revised tables and formulas that more accurately reflect the voltage needed to jump the air gap in a holiday without exceeding the coating's dielectric strength (its ability to withstand electrical stress). This change provides a more technically defensible basis for selecting the correct test voltage.

The Role of AMPP (formerly NACE) in Setting Industry Benchmarks

The Association for Materials Protection and Performance (AMPP) is the global authority on corrosion control and protective coatings. Formed from the merger of NACE International and SSPC, AMPP continues the legacy of developing and maintaining standards that represent industry consensus on best practices. NACE SP0188-2024 is a product of this process, drawing on the expertise of industry leaders, including coating manufacturers, applicators, equipment suppliers, and inspection experts. By establishing these benchmarks, AMPP provides a common language and a set of verifiable procedures that enhance safety, protect assets, and ensure quality across the global pipeline industry.

NACE SP0188-2024 in Practice

Applying the NACE SP0188-2024 standard correctly requires careful attention to procedure, equipment, and documentation. For new pipeline projects, where adherence to specifications is paramount, understanding these practical elements is key to a successful inspection program.

Selecting the Correct Test Voltage

This is the cornerstone of the updated standard. The inspector must first accurately measure the coating thickness in the area to be tested. Using the tables provided, the inspector selects the appropriate test voltage for that thickness range. It's crucial to abandon outdated rules of thumb. For example, the old "100 volts per mil" guideline is no longer considered a reliable method and is superseded by the tables derived from Paschen's Law. The goal is to set a voltage sufficient to arc across the largest likely air gap (the coating thickness) but well below the coating's dielectric strength. Always consult the coating manufacturer’s data sheet for specific recommendations, as they may also suggest a maximum test voltage.

High Voltage Holiday Detection Equipment and Calibration Protocols

A high voltage detector is a sophisticated piece of equipment that must be properly maintained and verified.

Calibration: The detector should have a current certificate of calibration from an accredited laboratory, typically performed annually. This confirms the device’s internal voltmeter is accurate.

Voltage Verification: Before and during use, the output voltage should be verified using a calibrated high voltage voltmeter (a "jeep meter") to ensure the detector is delivering the voltage set on its display.

Functional Check: A simple check on a known holiday or a manufactured defect should be performed to ensure the alarm system is working correctly.

Grounding: The detector must have a solid ground connection to the conductive substrate of the pipeline. A poor ground will result in an open circuit, rendering the test useless.

Inspection Procedures for New Pipeline Coatings

The inspector selects an appropriate electrode (a rolling spring for the main pipeline, a brush for irregular shapes) to ensure full contact with the surface. The electrode is moved over the entire coated surface at a steady speed, as specified in the standard (approximately 1 ft/s). The inspection must cover 100% of the surface area designated for testing. When the alarm sounds, the inspector should stop, confirm the location of the holiday by moving the electrode back and forth, and then clearly mark the defect for repair according to the project specification.

Documentation and Reporting Requirements

Thorough documentation is a important deliverable of any inspection process. The report for discontinuity (holiday) testing should include, at a minimum:

Identification of the pipeline or structure tested.

Details of the specific coating system.

The holiday detection equipment used (make, model, serial number).

The test voltage applied and date tested.

Records of equipment calibration and field verification.

The names and qualifications of the inspection personnel.

The results of the inspection, including the location and number of holidays found.

A record of all repairs performed and the subsequent re-inspection of those areas.

Common Myths and Misconceptions About Holiday Detection

Misinformation and outdated practices can compromise the integrity of a pipeline coating inspection. Let's debunk some common myths using the principles outlined in NACE SP0188-2024.

Myth 1: High-Voltage Jeep Testing "Burns Through" or Damages Pipeline Coatings

Misconception: A common belief is that high-voltage holiday detectors can burn through or damage pipeline coatings during testing, especially if the voltage is set too high. "Turn the Jeep down or you'll burn through."

Clarification and Technical Explanation: High-voltage holiday detection does not inherently "burn through" or damage coatings when used correctly. The principle of high-voltage testing is based on the electrical breakdown of air or the coating at a discontinuity (holiday). When the probe passes over an intact, non-conductive coating, no current flows. If a holiday is present, the voltage bridges the gap, allowing a small current to pass, which triggers an alarm or spark at the defect location. The voltage required to detect a holiday is set to exceed the breakdown voltage of air over the coating thickness, but it is designed to be well below the voltage that would cause dielectric breakdown of the coating itself if the coating is intact.

Any char or burn marks in the coating created during the 'spark' only happen if a defect was present to begin with. Continuously sparking a holiday can emphasize this effect.

Recent revisions to the NACE SP0188-2024 standard have addressed this misconception directly. The update specifically notes that the previously used "rule of thumb" of 100 volts per mil was not scientifically based. Instead, the correct test voltage is now determined using Paschen’s Law and empirical data to ensure that the voltage is sufficient to detect holidays but not so high as to risk damaging the coating. The standard provides tables of recommended voltages for various coating thicknesses, calculated to reliably detect holidays without causing electrical breakdown of the coating or substrate.

Key Points:

When following manufacturer and standard recommended voltages, high-voltage holiday detection does not burn through or degrade intact coatings.

Excessive voltage, poor calibration, or testing previously exposed coatings can cause damage or false readings if done incorrectly.

The correct test voltage is based on coating thickness and scientifically validated standards, not a fixed volts-per-mil rule

Myth 2: All Coatings Have the Same Dielectric Strength and Can Withstand Any Holiday Test Voltage

Misconception: Another myth is that all pipeline coatings have the same dielectric strength and can safely withstand any voltage applied during holiday testing. "We set the Jeep at 4.0 for everything."

Clarification and Technical Explanation: Dielectric strength (the maximum voltage a coating can withstand without electrical breakdown) varies significantly among coating types, thicknesses, and application conditions. For example, fusion-bonded epoxy (FBE) typically has a higher dielectric strength than coal tar enamel or some tape coatings, but this property is also influenced by surface preparation, cure, and environmental exposure.

NACE SP0188-2024 and related standards stress the importance of consulting the coating manufacturer for recommended test voltages based on the specific dielectric strength and thickness of the coating system. Applying a voltage that exceeds the dielectric strength of the coating can result in electrical breakdown, creating new holidays or enlarging existing ones. This risk is especially pronounced for thin, brittle, or improperly cured coatings.

Key Points:

Always determine the appropriate test voltage for the specific coating type and thickness using manufacturer data and standard tables.

Using a "one size fits all" voltage can cause unnecessary damage to coatings with lower dielectric strengths or thinner applications.

Myth 3: Holiday Detection Is Only Needed for Thick or High-Performance Coatings

Misconception: Some believe that holiday detection is unnecessary for thin or low-performance coatings, or that only high-performance (e.g., FBE) coatings require such inspection. "We don't need to jeep that."

Clarification and Technical Explanation: Holiday detection is a critical quality assurance step for all new protective coatings on conductive substrates, regardless of thickness or type. Thin coatings are particularly susceptible to pinholes, micro-cracks, and application defects that may not be visible but can significantly compromise corrosion protection. Both high-voltage (for thicker coatings) and low-voltage (for thin coatings) holiday detection methods are covered in NACE SP0188-2024.

Key Points:

Holiday detection is essential for all new coatings, not just thick or high-performance types.

Low-voltage (wet sponge) testing is recommended for coatings up to 20 mils; high-voltage testing is used for thicker coatings.

Myth 4: Holiday Detection Is a Substitute for Proper Surface Preparation and Application

Misconception: A persistent misconception is that holiday detection can compensate for poor surface preparation or improper coating application. "If it passes Jeep then it's good."

Clarification and Technical Explanation: Holiday detection is a post-application quality control tool and cannot remedy deficiencies in surface preparation or application. Over 75% of coating failures are due to inadequate surface preparation, not missed holidays. Even if a coating passes holiday detection, poor adhesion, contamination, or improper cure can lead to premature failure in service. Holiday detection is only effective when used as part of a comprehensive quality assurance program that includes specification-driven surface preparation, application, environmental controls, and inspection.

Key Points:

Holiday detection does not correct or compensate for poor surface preparation or application.

A coating can pass holiday testing but still fail prematurely if underlying preparation or application was inadequate.

Myth 5: Holiday Detection Is Optional or Not Required by Standards and Regulations

Misconception: Some believe that holiday detection is an optional step, not required by industry standards or regulations. "This isn't something we need to Jeep."

Clarification and Technical Explanation: Holiday detection is a mandatory quality control step in numerous industry standards and federal regulations for pipeline construction and maintenance. For example, 49 CFR 192.461 requires that all external protective coatings be inspected for damage and tested for holidays before backfilling, with any defects repaired before the pipeline is put into service. NACE SP0188-2024, NACE SP0105-2024 (for field-applied liquid coatings), and NACE SP0394-2023 (for plant-applied FBE) all require holiday detection as part of the acceptance criteria for coating quality.

Key Points:

Holiday detection is a required step by standards such as NACE SP0188-2024, NACE SP0105-2024, and NACE SP0394-2023.

Federal regulations (49 CFR 192.461) mandate holiday testing and repair of detected defects before backfilling.

Myth 6: The "100 Volts per Mil" Rule Is Always Appropriate for Setting Holiday Detector Voltage

Misconception: A widely cited rule of thumb is to set the high-voltage holiday detector at 100 volts per mil of coating thickness, regardless of coating type or environmental conditions.

Clarification and Technical Explanation: The "100 volts per mil" rule is outdated and not scientifically valid for all coating types and thicknesses. NACE SP0188-2024 now recommends setting the test voltage based on Paschen’s Law and empirical data, which account for the breakdown voltage of air and the dielectric properties of the specific coating. The standard provides a table of recommended voltages for various coating thicknesses, ensuring reliable detection without risking coating damage.

Key Points:

Always use the voltage settings recommended in NACE SP0188-2024 or by the coating manufacturer, not a fixed volts-per-mil rule.

The Value of Expertise and Diligence in Pipeline Holiday Detection

Successfully implementing NACE SP0188-2024 is not just about owning the right equipment; it's about the knowledge, diligence, and expertise of the personnel performing the inspection. This human factor is often the difference between a compliant test and a failure.

The Role of Certified Coating Inspectors

A certified coating inspector brings an essential layer of assurance to any pipeline project. Inspectors holding certifications from organizations like AMPP or FROSIO have demonstrated proficiency in coating principles, application, and inspection techniques. They understand the nuances of standards like SP0188-2024, from the importance of equipment calibration to the scientific basis for test voltage selection. It's not just a box checking exercise but a meaningful assessment of coating quality that provides documentation for the asset owner.

Conclusion

The release of NACE SP0188-2024 marks a pivotal moment for the pipeline industry, reinforcing a commitment to science-based quality assurance. For new pipeline construction, where the stakes are highest, this standard is not just a guideline but a critical tool for long-term asset protection. By moving beyond outdated rules of thumb to embrace a rigorous, repeatable methodology for discontinuity (holiday) testing, the standard provides a clear path to verifying the integrity of essential protective coatings.

For project managers, engineers, and inspectors, the next steps involve fully integrating NACE SP0188-2024 into project specifications, training programs, and quality management systems. Embracing this updated standard is a direct investment in the longevity, safety, and operational efficiency of the world's critical energy infrastructure, ensuring that new pipelines begin their service life with the robust protection they require to perform reliably for decades to come.

Roberts Corrosion Services, LLC

Established in 2011, Roberts Corrosion Services, LLC delivers comprehensive, turn-key cathodic protection and corrosion control solutions nationwide. Our end-to-end expertise encompasses design and inspection, installation and repair, surveys and remedial work. We provide drilling services for deep anode installations and a full laboratory for analysis of samples and corrosion coupons, as well as custom CP Rectifier manufacturing.

While our initial focus was on the Appalachian Basin area, we complete field work all over the US. We are a licensed contractor in many states and can complete a wide range of services.

Our biggest strength is in our flexibility for our clients. Solutions and Results.

Let us know how we can help.

Website

LinkedIn

Location: 39.251882, -81.047440

(304) 869-4007