Deep Anode Wells Explained: An Introduction to Deep Groundbeds and Cathodic Protection

Beneath our feet lies a vast network of metallic infrastructure that are essential to modern life. These assets face a constant, silent threat: corrosion. This natural electrochemical process relentlessly degrades metal, compromising structural integrity, leading to costly failures, and posing significant environmental risks. To combat this, engineers employ a technique called cathodic protection, and one of its more advanced applications is the deep anode well. This article provides a comprehensive introduction to deep groundbeds, explaining their components, function, and critical role in safeguarding vital infrastructure.

The Silent Threat: Understanding Corrosion and the Need for Protection

What is Corrosion?

Corrosion is the natural process where a refined metal converts to a more chemically stable form, such as its oxide, hydroxide, or sulfide (rust). For buried steel pipelines or tanks, this process occurs when the metal, soil, and environmental moisture form a natural electrochemical cell. Areas on the metal surface become anodic (where corrosion occurs) and cathodic (where it is protected). The flow of electric current between these areas results in the gradual loss of metal at the anode, leading to leaks, ruptures, and eventual failure.

Introducing Cathodic Protection (CP)

Cathodic protection (CP) is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A properly designed CP system effectively halts the corrosion process by overpowering the natural corrosion currents. This is achieved by supplying a protective electrical current from an external source, forcing the entire structure to become a cathode. There are two primary types of CP: sacrificial anode systems and impressed current cathodic protection (ICCP) systems. Deep anode wells area sophisticated form of ICCP.

The Role of Groundbeds in Cathodic Protection Systems

An Impressed Current Cathodic Protection (ICCP) system uses an external power source (rectifier) to drive a protective current from an anode groundbed to the target structure. In an ICCP system, a groundbed is essential. It is a configuration of one or more anodes buried in the earth to discharge the protective current. This current flows from the groundbed through the soil to the structure being protected (the cathode). The design and location of the groundbed system are critical for ensuring that the protective current is distributed evenly and effectively across the entire surface of the target structure, providing comprehensive corrosion control.

Groundbed Fundamentals: Shallow vs. Deep Solutions

Different Types of Groundbeds

Groundbed systems can be broadly categorized by their depth and configuration. Surface groundbeds involve anodes placed very near the surface, often in a horizontal trench. Shallow groundbeds typically place anodes vertically or horizontally at depths of less than 50 feet. Finally, deep well groundbeds, also known as deep anode wells or cathodic protection wells, place the anodes at depths well below 50 feet, often reaching several hundred feet.

Limitations of Surface and Shallow Groundbeds

While effective in some applications, shallow groundbeds have significant limitations. They require a large surface area, making them impractical in congested urban or industrial areas. Their performance is highly susceptible to seasonal variations in soil moisture and temperature, which can cause resistance to fluctuate. Furthermore, their proximity to the surface can lead to electrical interference with other buried metallic structures, a phenomenon known as stray current corrosion, which can cause unintended damage to nearby assets.

The Emergence of Deep Well Groundbeds

Deep well groundbeds were developed to overcome the challenges posed by shallow systems. By placing anodes at significant depths, engineers can access more stable geological strata with consistently low soil resistivity. This remote placement minimizes surface footprint, reduces electrical interference, and provides a more uniform and efficient distribution of protective current, especially for large or complex structures like pipelines, tank farms, and bare or poorly coated structures.

Deep Anode Wells: A Strategic Solution for Comprehensive Corrosion Control

What is a Deep Anode Well?

A deep anode well is a vertically drilled hole, typically 50 to 600 feet deep, containing a series of anodes suspended within a conductive carbonaceous backfill. This entire assembly, known as a deep groundbed, is connected to a DC power source. It functions as a single, high-performance anode, discharging a large amount of cathodic protection current from a remote location deep within the earth to protect a target structure on or near the surface.

Why Choose Deep Anode Systems?

Deep anode systems are chosen when surface conditions are prohibitive or when superior current distribution is required. They are the ideal solution in areas with high surface soil resistivity, limited real estate, or significant infrastructure congestion. By positioning the groundbed far from the protected structure and other utilities, they provide a more "electrically remote" current source, resulting in better spread of protection and significantly less risk of interference.

Key Advantages of Deep Anode Groundbeds

The primary advantages of deep anode groundbeds include their minimal surface impact, making them perfect for developed areas. They offer highly stable and predictable performance due to their placement in geologically stable, low-resistivity layers, unaffected by surface conditions. This stability translates into lower power consumption and significant long-term cost savings. Furthermore, their ability to deliver a high current output from a single location makes them exceptionally efficient for protecting large-scale assets.

Anatomy of a Deep Anode System: Components and Their Functions

The Heart of the System: Anodes

The anodes are the core components that discharge the protective current. The anode type chosen depends on the required current output and desired design life. Common materials for these protective anodes include high-silicon cast iron, mixed metal oxide (MMO), and graphite. They are typically cylindrical and arranged in a string within the well. The total anode area and material selection are critical design parameters that influence the system's longevity and performance.

Optimizing Current Flow: The Backfill Material

To ensure efficient current transfer from the anodes to the surrounding earth, the anodes are encased in a specialized, highly conductive material called carbonaceous backfill, often referred to as coke breeze. This backfill serves two main purposes: it provides a low-resistance, uniform environment around the anodes, and it is consumed before the anode material itself, extending the life of the anode system. The backfill is typically installed as a slurry to ensure it is compacted tightly around the anodes, maximizing the anode area interface.

The Well Structure: Casing and Venting

The top portion of the drilled hole is often lined with well casings, typically made of PVC or steel, to maintain the structural integrity of the well and prevent contamination of groundwater aquifers. A critical component is the vent pipe, which runs the length of the anode column. The electrochemical reaction at the anodes generates gases (primarily chlorine and oxygen). The vent pipe allows these gases to escape to the surface, preventing "gas blockage," which can increase the groundbed's resistance and hinder performance.

The Power Supply and Connectivity

A deep anode well is an impressed current system, meaning it requires an external power source. This is provided by a rectifier, which converts AC power from the grid into the controlled DC current required for cathodic protection. The rectifier is the system's current source. Robust header cables connect the anodes within the well to a junction box at the surface, which in turn connects to the rectifier, completing the electrical circuit.

Deep Anode Well Installation: A Specialized Engineering Process

Pre-Installation: Site Assessment and Planning

Successful installation begins with a thorough site assessment. This includes geological surveys and soil resistivity testing at various depths to identify the optimal location and depth for the groundbed. The goal is to find a low-resistivity stratum that will facilitate efficient current discharge. This planning phase is crucial for designing an effective and long-lasting anode system.

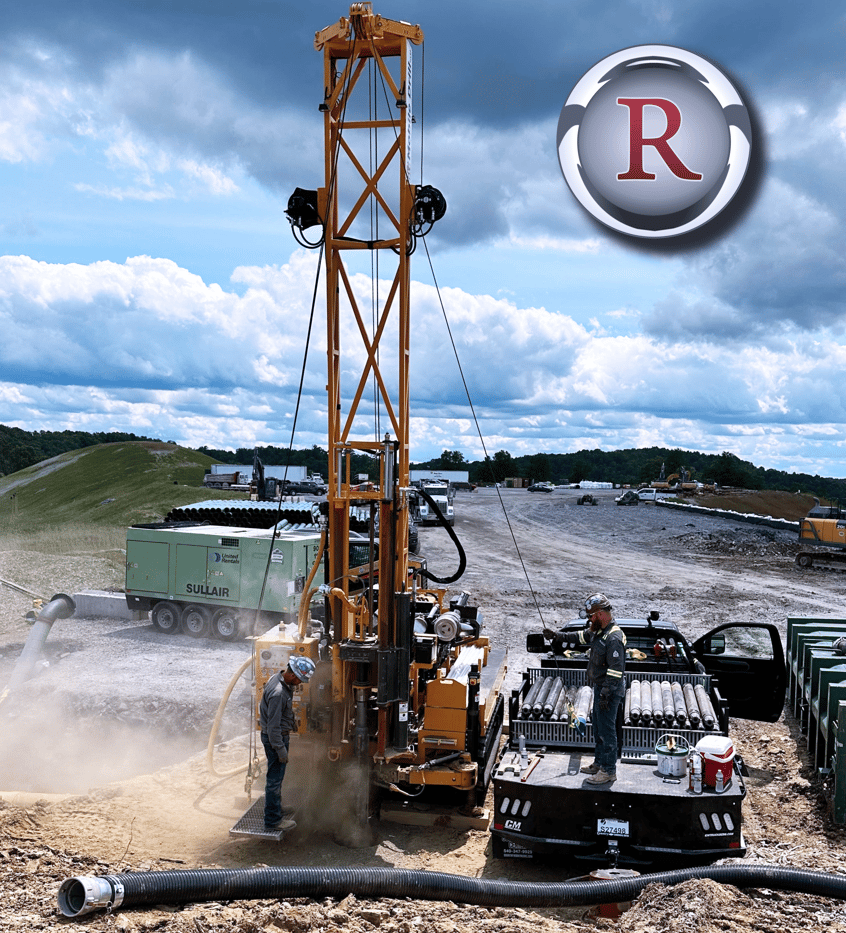

Drilling and Well Preparation

Once a site is selected, a specialized drilling rig is used to create the borehole to the specified depth. The diameter and depth are determined by the system's design requirements. After drilling, the hole is prepared for the groundbed assembly, which may include installing the well casings to isolate the active anode zone from environmentally sensitive areas like aquifers.

Groundbed Assembly and Placement

The anodes are carefully assembled into a string, often attached to or suspended around the central vent pipe. Spacers are used to ensure they remain centered within the borehole. The entire assembly is then carefully lowered into the well. Once the anodes are in place, the carbonaceous backfill is pumped into the well as a slurry, filling the annular space around the anode string.

System Integration and Commissioning

After the backfill settles, the surface components are installed. This includes sealing the top of the well, making the electrical connections at the junction box, and wiring it to the rectifier. The final step is commissioning, where the system is energized, and initial tests are conducted to ensure it is operating correctly and delivering the required protective current to the target structure.

How Deep Anode Wells Work: The Science of Protection

The Electrochemical Principle: Electric Potential and Current Flow

A deep anode well functions by altering the natural electrochemical environment. The rectifier impresses a DC voltage between the anode groundbed and the structure being protected (e.g., a pipeline). This makes the entire groundbed strongly anodic and the pipeline strongly cathodic. The resulting potential difference drives a protective current from the anodes, through the earth, and onto the surface of the pipeline, suppressing the natural corrosion cells.

The Earth Interface: Facilitating Current Transfer

The effectiveness of a deep anode well hinges on its interface with the earth. By placing the anodes in a deep layer of soil with low electrical resistivity (e.g., wet clay or shale), the system can discharge a large amount of current with minimal voltage. The conductive backfill creates an enlarged effective anode area, further reducing resistance and improving the efficiency of current transfer.

Direct Current (DC Source) and CP Current Delivery

The rectifier, acting as the DC source, is the engine of the system. It provides a constant, controlled flow of DC current. This current travels down the header cable to the anodes, discharges into the soil via the backfill, and is collected by the pipeline or protected structure. A return cable connected from the structure back to the negative terminal of the rectifier completes the circuit, allowing for continuous protection.

The Role of Anodes and Cathodes in Protection (anode, cathode area)

In this system, the anodes in the deep well are sacrificial components designed to corrode preferentially. The entire surface area of the structure being protected—the cathode area—is forced to become the site of a non-corrosive reduction reaction. The large, distributed cathode area of a pipeline receives current from the relatively small, concentrated anode area of the deep groundbed.

Current Density and Its Importance for Effective Protection

Current density—the amount of current per unit of surface area—is a critical parameter. The system must deliver sufficient current density to all parts of the structure to achieve a protective potential and halt corrosion. The remote placement of a deep anode well helps distribute this current more evenly over large structures compared to shallow systems, preventing areas of under-protection or over-protection.

Managing Gas Generation at the Anode (gas molecules, vent pipe)

As current discharges from the anodes, electrochemical reactions produce gas molecules, primarily chlorine from chlorides in the soil and oxygen from water. If these gases become trapped around the anodes, they can form an insulating barrier (gas blocking), dramatically increasing the circuit resistance. The vent pipe provides a crucial pathway for these gases to escape, ensuring the long-term stability and efficiency of the groundbed.

Conclusion

Deep anode wells represent a sophisticated and highly effective method of cathodic protection, engineered to overcome the limitations of traditional groundbed systems. By leveraging deep, stable geological layers, they provide consistent, efficient, and long-lasting protection for critical infrastructure in challenging environments. While the initial installation is a complex engineering process requiring specialized expertise, the long-term benefits—including minimal surface disruption, reduced operational costs, superior current distribution, and enhanced reliability—make deep well groundbeds an indispensable tool in the fight against corrosion. For asset owners facing complex protection scenarios, consulting with a corrosion engineering expert to evaluate the suitability of a deep anode system is a crucial step toward ensuring the long-term integrity and safety of their investments.

Roberts Corrosion Services, LLC

Established in 2011, Roberts Corrosion Services, LLC delivers comprehensive, turn-key cathodic protection and corrosion control solutions nationwide. Our end-to-end expertise encompasses design and inspection, installation and repair, surveys and remedial work. We provide drilling services for deep anode installations and a full laboratory for analysis of samples and corrosion coupons, as well as custom CP Rectifier manufacturing.

While our initial focus was on the Appalachian Basin area, we complete field work all over the US. We are a licensed contractor in many states and can complete a wide range of services.

Our biggest strength is in our flexibility for our clients. Solutions and Results.

Let us know how we can help.

Website

LinkedIn

Location: 39.251882, -81.047440

(304) 869-4007